Chemistry solutions as easy as 1, 2, 3

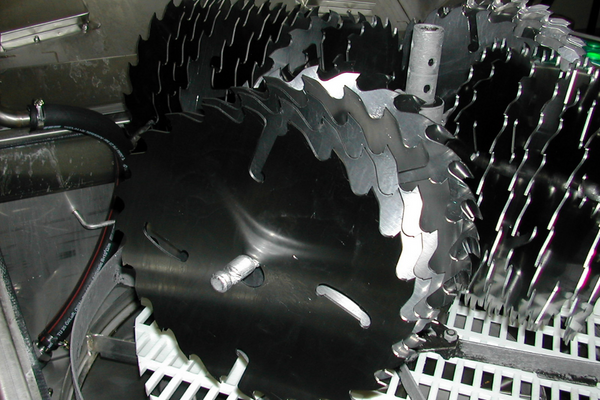

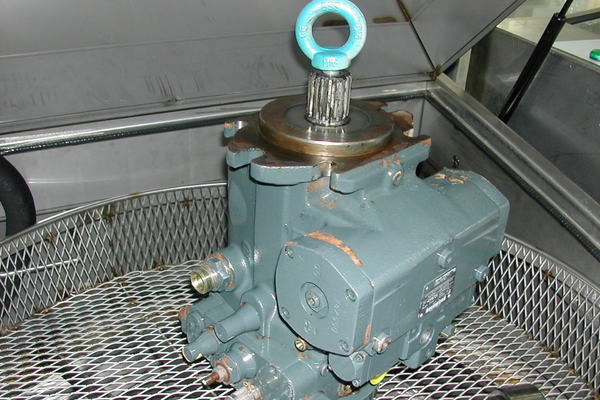

ADS 800 not only provides a payload capacity of 250kgs and an 800mm basket diameter, enabling you to clean large parts quickly and easily, it also operates using one of three chemistry solutions. The solution you use depends on the substrate, contaminant and desired cleaning standard but all are water based, free from VOCs and contain corrosion inhibitors to protect your parts.

| Storm 1 Soft/ white metals |

Power Clean General purpose |

Super Bee™ Aviation chemistry |

|

|---|---|---|---|

| Contaminants | Oil, grease, cutting fluid, dirt, carbon | Scale, carbon, heavy duty soils | Oil, grease, cutting fluid, carbon, scale |

| Substrate | Aluminium, brass, copper, stainless steel, plastics |

Mild steel, cast iron | All, particularly aluminium, copper, zinc |

| Industry types | Medium to light applications | Heavy duty | Aviation approved |

| Advantages | Excellent on white/soft metals. NSF approved | Excellent on automotive gearboxes/engines | Aviation approved, industry standard |

| Disadvantages | Can foam up if not to temperature | Can leave white residue on some applications | Only use for Aviation |

| Volume per fill | 4 litres | 4kg tub | 5 litres |